I found setting up a supply chain in China to be enlightening, and I’d like to share more of my experiences with the readers of this blog.

Presenting this material is challenging; there is a lot of detail and its easy to get overwhelmed and lost in the vagaries of electronics manufacturing. In order to focus my writing and create a more succinct body of works, this series of posts will be thematic. In other words, instead of talking about the details of how pick and place machines work in China, I’ll post about a more abstract theme such as “automation” and just show sound bites to give the reader a flavor of what’s going on.

The theme of this first post is “Getting Started”.

In September of 2006, Chumby was just a team of about a half dozen people, and we had given away about 200 early prototype chumby devices at Tim O’Reilly’s FOO camp. The devices were well received by the attendees of the conference, so I got the go-ahead to build the Asian supply chain.

Before we went to China, we had a trusted vendor in the US give us their best quotation for the job, so we had a reference point to work downwards from.

In a nutshell, we called up a lot of our friends who had some experience in China, and we lined up a series of about a half dozen factory tours in China. We hit quite a variety of places on our tour, from specialty factories as small as 500 people to mega-factories with over 40,000 people.

Being open source helped a lot in terms of kick-starting the process, because first we had no fears about people stealing our design–we’re giving the design away–and there were no NDAs to sign when sharing critical information, like the bill of materials. I think this kind of openness actually gave us a better reception with the factories in China; they seemed more willing to open up to us because we were willing to open up to them. Also, there was no question in the factory’s mind that they were in a competitive situation. It was plain that anybody could and would quote and bid on the job (in fact, we received a few unsolicited quotations that were quite competitive), so it saved a round of huffing and puffing. And finally, it seems that despite handing out our BoM without an NDA, nobody in the general public is aware of the strategic improvements we rolled into the chumby hardware since the FOO prototype (then again, chumby has no serious competition at this point in time).

In November, Steve Tomlin and I went to China to do the factory visits, and some of my first impressions were documented in my post Adventures with the Venture Communist.

There is no substitute for going to China to tour the factory. Pictures are always deceiving, and you just can’t get a sense for the scale and quality of the factory without going to see the actual facility. In general, factories welcome you to take a tour–I wouldn’t work with one that didn’t allow me to come visit. However, most factories do appreciate a week prior notice before you come and visit, although as your relationship with the factory progresses things should become more open and transparent.

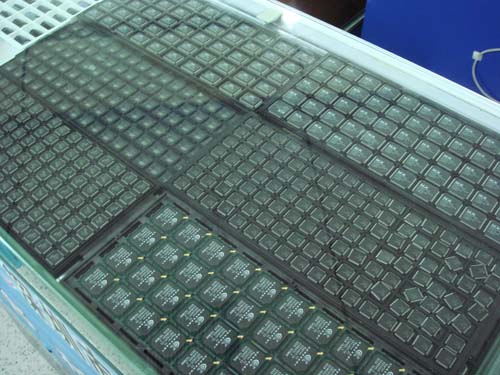

While almost every factory will “clean up” the day you come to visit, a sharp eye and the right questions can see through any quick veneers put in place. One place I always liked to visit was the QC room. I expect to see rows of well-maintained and well-worn binders with design documentation and QC standards, as well as “golden samples”. I would point at a couple of random binders and demand to view their contents, see the product’s golden sample, and verify that they knew what was going on in the binder–that it wasn’t just some random data they threw in there. Also, hard investments in equipment is a good sign: the best manufacturers I visited all had a couple rooms with sophisticated equipment for thermal, mechanical, and electrical limit testing, and of course operators were in the room actually using the equipment (I could definitely believe a Chinese manufacturer would buy a room of equipment just for show and not actually use it).

After reviewing several manufacturing options, we decided on one, which was PCH China Solutions. PCH itself owns only a few facilities, but it has a comprehensive network of trusted and validated vendors–primarily in China but also Europe and the US as well. Not surprisingly, the factories that PCH sub-contracts to were some of the best facilities we visited while we were in China.

PCH is actually headquartered out of Ireland, and as such, most of their staff engineers are Irish, so there was no langauge barrier. They are hard working, resourceful, well-trained, and as a bonus they always seemed to know the best places to find a pint no matter where we are. I had no idea China had so many Guiness taps.

In retrospect, this is definitely the way to go–I learned a lot about what it takes to do business in China by shadowing their engineers while I was out there. From 10,000 miles away it looks easy but it’s anything but easy working with even the best Chinese contract manufacturers. I’ll cover some of the “frustration stories” in another themed post later on.