The chumby One is finally released. You can buy it now for a $99 “chumby insider” pre-order price; once we start shipping, the price will go up to $119.

While I’ve been working on several new hardware platforms for chumby, this is the first of the crop to hit the market. This one made it out before the Christmas season because it is an evolution of the original chumby design, now called the “chumby classic”, as opposed to a completely new form factor for the device.

The key goal of the chumby One platform was cost reduction: my first sketches for the device were drawn on the back of a napkin about a year ago, back when the stock market was in a free-fall and losing several hundred points a day. Unfortunately, the chumby classic hit full-stride launch in the middle of the worst economic downturn since the Great Depression, and its cute cuddly form factor comes at a fair bit of a price tag that many couldn’t stomach. So, I did what any entrepreneur would do in a recession, I suppose … scale back, and take a good hard look at everything and try to build a product that is cheaper, faster, and better for the market, to try and win new customers, and to retain the loyalties of our existing customer base.

Fortunately, around that time, a Freescale apps engineer contacted me about a new CPU (the i.MX233) they were going to launch in 2009 that could hit a remarkably low price point. So, I drew up some strawman renderings and did some cost scenarios, and in CES 2009, we circulated the idea around with a few potential customers to get feedback on the features and pricing. The idea sort of slow-rolled through the first few months of 2009, and after chinese new years, I taped out the first prototype board in late March. Around May we contracted an industrial designer to do some sketches, and by June we had a near-final ID; our first 3D printed prototypes were made around then (we couldn’t afford a mechanical engineering contractor I had to learn Solidworks and do the mechanical integration for the 3D prototype myself — since I enjoy learning new things, this was quite a rewarding experience). In July, we inked a PO for steel tooling and by August we had first-shot plastics. September was spent refining and debugging the design, and October was spent doing more testing, refining, and ramping up mass production. And, here we are now, in November. When I wrote this, the first shipment of chumby Ones were somewhere 35,000 feet above the Pacific Ocean en route to LAX. As for the i.MX233, I believe we are one of the first devices on the market to use it…I even got a quote in their launch press release last August, although I couldn’t refer to the chumby One by name at that time.

Just to give you an idea of what the final assembly line for the chumby One looks like, below is a video of a part of the assembly line:

[flashvideo file=http://www.bunniestudios.com/blog/images/c1mp_line.flv /]

In addition to being about half the price of the original chumby, the new device added some features: it has an FM radio, and it has support for a rechargeable lithium ion battery (although it’s not included with the device, you have to buy one and install it yourself). There’s also a knob so you can easily/quickly adjust the volume. But I don’t think those are really the significant new features. What really gets me excited about this one is that it’s much more hackable. The most significant improvement is that the firmware is stored on a microSD card.

The microSD card isn’t replaceable from the outside — this is to prevent non-hackers from pulling it out and wondering why the device isn’t booting anymore — but if you take the back panel off (screws this time, no glue seals), it’s fairly easy to access. The key here is that no longer do you have to worry about bricking your chumby device: if you screw up the firmware, you just pull it out, mount it on your dev box, and dd a new image onto it. Also, microSD is a “managed” NAND device, unlike our previous generation device which used a raw NAND device. This means that we don’t have to rely on a MTD layer for the filesystem, and instead we can directly drop ext3 onto the device. While we still mount the root partition as read-only to harden the device against accidental damage, unlike our original cramfs implementation, you can trivially remount it as read/write and modify the linux on the device. Also, our OS image takes up only a small portion of the total device capacity, so there’s actually over a gigabyte of extra space on there for you to load extra applications and libraries.

Significantly, what’s good for the hackers is also good for the developers. Because of this additional flexibility, we could add a ton of great features into the OS. For example, the chumby one supports certain 3G modems, and will serve wifi as an access point through the 3G modem (it can also serve as an access point for an ethernet connection provided via a USB-to-ethernet dongle as well). This is really slick, because that makes it basically a 3G to wifi router; it is enormously useful when I’m traveling and I need to create a wifi hotspot for other devices to use. Of course, this feature isn’t exposed yet at the mainstream user level, but if it turns out to be a popular application it’s something we could wrap a GUI around and make it more friendly to use. There are also other little refinements, such as if you plug a USB keyboard into a chumby One, it will automatically pop up a console shell that you can type into; very handy for times when you can’t ssh in, like when you are debugging network scripts. It also has high-speed USB2.0 support, so unlike our previous generation device, you can plug a USB camera into this one and grab images at a decent speed. And yes, we’ve booted Android on the chumby One. Android runs on linux after all, so why not? Eventually we’ll get these hacks documented on the chumby wiki (heck, maybe even compile them into a book), but right now we’re a little pre-occupied with making sure the product launch goes smoothly. Actually, to give credit where it’s due, most of these cool hacks were implemented by xobs (remember him? he ported quake on the chumby classic), not me — I’m just the hardware guy, xobs is the software guru.

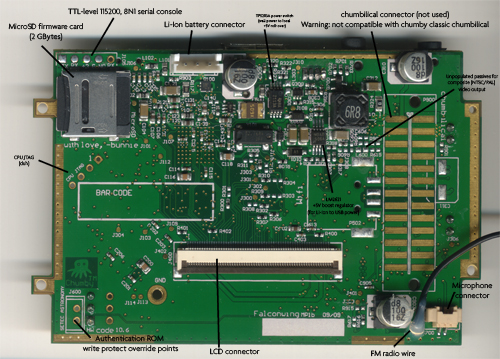

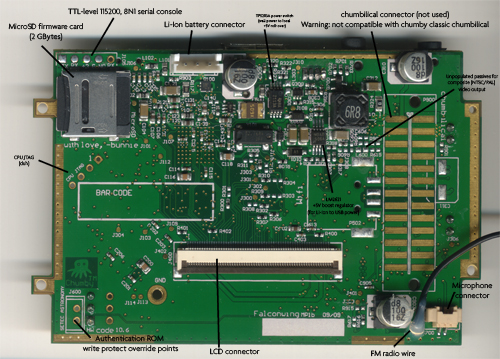

Below are some annotated photos of the chumby One mainboard. Schematics and gerbers are forthcoming, should be up in about a week or two; the GPL source code is already up.

This is actually a pre-production pilot board. The mass production board is basically identical to this, with some minor tweaks to enhance compatibility with the SMT machines we use in China. There’s a couple of noteworthy points about the board. First, the footprints are available on the board for you to populate some parts to break out a composite video signal (NTSC or PAL). We’ve actually wired this up and confirmed that it works, and it’s pretty neat for presentations where you want to plug into a projector and show a crowd of people some widgets. There’s also a pair of test points on the board labeled “SETEC ASTRONOMY” that you can use to bypass the write protect on our authentication ROM, in case you want to wipe out the keys we use to authenticate your chumby. I can’t think of a real reason why you’d want to do that, but I added them on the principle that hardware you own shouldn’t hold secrets from you, so if you don’t like it you can nuke the encrypted access codes we put into each device (of course, it means you no longer have the codes to fetch widgets from our servers, but hey, it’s your hardware, void the warranty and do what you want with it). The security system is actually a bit convoluted on this device, but it uses basically the same, published protocol we employed on the chumby classic with some enhancements to leverage the internal AES engine on the i.MX233 to save the cost of an external cryptoprocessor unit.

One other really cool thing about the motherboard that I’d like to point out is that the power regulators are embedded inside the CPU. And they aren’t just linear regulators, they are switching regulators. And they just aren’t any switching regulators — this switching regulator derives three voltages using just a single inductor. How cool is that? Mad props to the guy who designed that system. The insanely high level of analog integration on this CPU — it pulls in the audio codec, power regulators, speaker amplifier, USB PHY, video DAC, battery charger and more — is one of the key things that has allowed me to create a system that you can buy at an affordable price.

If you’ve seen any of the chumby classic boards, you’ll instantly recognize that there are also mounting holes and features so this board can be retrofitted back into a chumby classic. That’s very intentional, although chumby doesn’t currently have a schedule to put this into a chumby classic; the classic line costs a lot to produce for more reasons than the PCB (think hand-stitched Italian leather). There’s also a couple of technical issues with integration, the most significant being the brutal thermal environment inside the chumby classic: the CPU contains the battery charging circuitry, and unlike the main supply, the charger circuit is a linear regulator so when charging it puts out a lot of heat. This is why we added a heatsink to the CPU, so we could charge the battery at maximum rate without having to throttle the CPU’s activity. I’m not quite sure how I would solve this problem if I were to put the board into a chumby classic, since there are no cooling holes in the device. I also get the sense that there wouldn’t be very much interest in a chumby classic that was a little bit cheaper, but still lacking the much-requested rechargeable battery: I am stuck between a rock and a hard place. However, the initial reactions to the battery in the chumby One are an interesting study in consumer psychology. For some reason, even though the chumby One is smaller and lighter than the chumby classic, and does largely exactly the same things, people don’t feel like it should have a rechargeable battery; they have no intrinsic desire to pick up the chumby One and carry it around. Just goes to show how much form influences a consumer’s perception of function. Also, as a very important note to intrepid hackers who want to try to retrofit one of these boards into their chumby classic: even though the footprint is identical, the chumbilical is absolutely not compatible with the chumby classic. For one thing, the chumby classic gets 12V from the chumbilical, and this device expects 5V. So if you were to just solder on a header and plug it into a chumby classic housing, you would get quite a cloud of smoke out of the device!

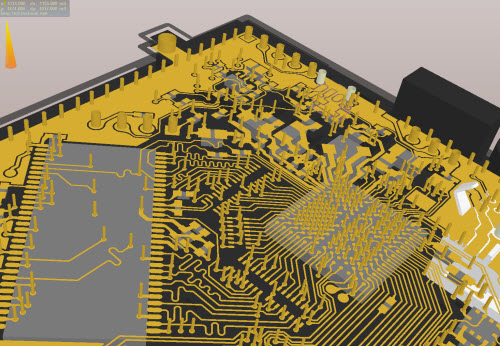

Also, as a little game for the readers, I will award a chumby One as a prize to the first person who can most accurately guess the number of vias on the chumby One circuit board based on the photos in this post. It’s a bit like one of those competitions where if you can guess the number of jellybeans in a jar you get the jar of jellybeans. This is vias not counting through-hole pads. Since the gerbers aren’t posted yet, you can’t cheat and use a CAD program to count the number of vias. :-) I’ll end the contest once the gerbers are posted, in about a week or so.