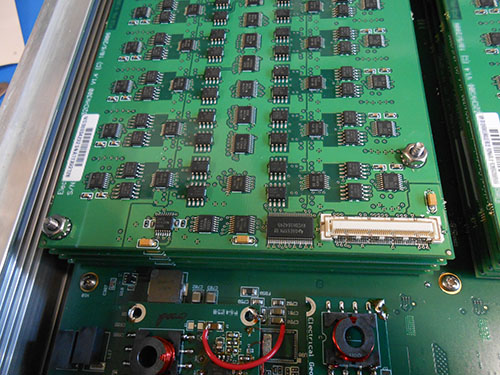

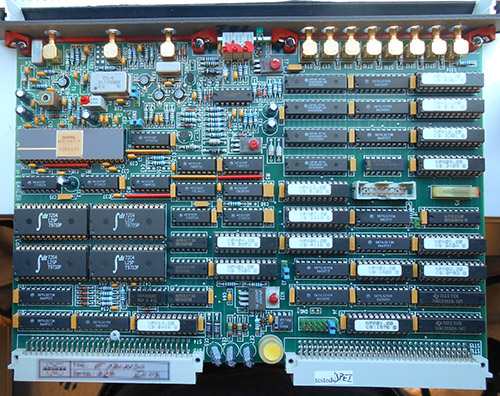

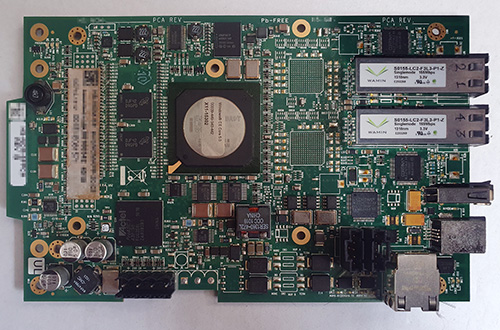

The Ware for March 2021 is a fire control system (not fire as in “artillery fire”, but fire as in “your building is on fire”) controller, a Honeywell HS-NCM-SF. It’s the sort of board that lives in those red boxes hanging near the entrance of big buildings with fancy fire alarm systems.

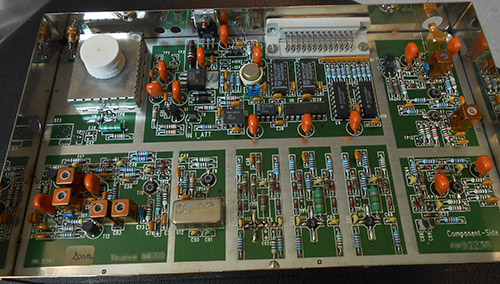

A quick Internet search shows these things go for around US$2k retail. This pricing is commensurate with a “made in USA” process, B2B volumes, and its choice of top-shelf parts, even though its specs are fairly modest if not strange. When I first saw this, I scratched my head at the use of fiber optic comms, matched with a CPU that was clearly not capable of handling fiber optic data rates. Once I learned its purpose, it made a bit more sense. At least, I’m presuming the fiber optics are chosen either because there is a reliability advantage in the context of fire-resistance of the cabling, or perhaps the fiber optics are advantageous because there is no risk of sparking wires in the case that one end of the line is engulfed in fire and presumably melts into a glob of metal that includes the power mains.

Again, Willmore nailed it. Congrats, email me for your prize!