usesthis.com recently posted an interview where I discuss what hardware and software tools I currently like to use to get my work done. This is a nice follow-on to a post I did about four years ago titled “The contents of my bag” where I summarized the things I carry around with me all the time. The only thing missing from the usesthis interview compared to my previous review is the bag that I use. Currently, it’s a Timbuk2 bag that’s been discontinued, but has the nice feature that it has both a shoulder strap and backpack-style straps with a muted charcoal-and-gray color scheme that is very versatile: it works for both more formal business meetings in Japan, as well as more mobile, casual situations such as hoofing it around the show floor at CES in Vegas. The bag has held up surprisingly well to abuse, although the left shoulder strap is starting to tear off and the tines on one of the snap-buckles for the main flap has broken, rendering it useless. This means my old Coach laptop bag is still the winner for durability, but unfortunately the single-strap design of the bag makes it tough to use when traveling.

Archive for the ‘Ponderings’ Category

bunnie uses this

Saturday, April 17th, 2010On MicroSD Problems

Tuesday, February 16th, 2010The microSD ware for January 2010 was not an incidental post. It is actually snapshot of a much longer forensic investigation to find the ground truth behind some irregular Kingston

memory cards.

It all started back in December of 2009, when chumby was in the midst of production for the chumby One. A call came in from the floor noting that SMT yield had dropped dramatically on one lot, so I drove over to the building to have a look (this is the advantage of being in China during production — you can fix problems like this within the hour, before they become really serious issues). After poking and prodding a bit, I realized that all the units failing had Kingston microSD cards from a particular lot code. I had the factory pull the entire lot of microSD cards from the line and rework all the units that had these cards loaded. Sure enough, after subtracting these cards from the line, yield was back to normal again.

Normally, the story would end there; you’d RMA the material, get an exchange for the lot, and move on. Except there were a couple of problems. First, Kingston wouldn’t take the cards back because we had programmed them. Second, there was a lot of them — about a thousand all together, and chumby was already deeply back-ordered. Also, memory cards aren’t cheap; the spot price on this type of memory card is around $4-5, so it’s a few thousand dollars in scrap if we can’t get them exchanged … and neither chumby nor the CM is large enough to sneeze at a few kilobucks.

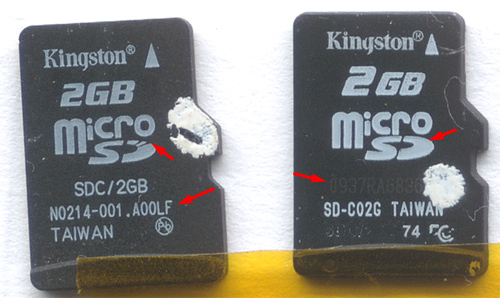

So I kicked into forensic mode. The first thing that raised my suspicions is the external markings on the irregular Kingston cards.

On the left is a sample of the irregular card. On the right is a sample of a normal card. I’ve put red arrows on the details that called the most attention to me at first.

The most blatantly strange issue is that the card on the left has its lot code silkscreened using the same stencil as the main logo. Silkscreening a lot code on isn’t that unusual, but typically the silk does not share the same stencil as the logo, so you’ll see some small variance in the coloration, font, or alignment of the lot code from the rest of the text. In fact, across the entire batch of irregular cards, they shared the exact same lot code (N0214-001.A00LF) (typically the lot code will vary every couple hundred cards at least). This is in contrast to the card on the right, which is laser-marked, and has a lot code that varied with every tray of 96 units.

The second strange issue, perhaps more subtle and perhaps not damning, is the irregularity in the “D” of the microSD logo. Typically, brand name vendors like Kingston would be very picky about the accuracy of their logos. The broken D is something found on SanDisk cards, but Kingston cards found in US retail almost universally use a solid D.

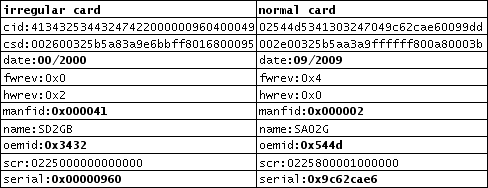

It turns out the weirdness in the external markings is just the start of it. When we read out the electronic card ID data on the two cards (available through /sys entries in linux), this is what we found:

First, the date code on the irregular card is uninitialized. Dates are counted as the offset from 00/2000 in the CID field, so a value of 00/2000 means they didn’t bother to assign a date (for what it’s worth, in the year 2000, 2GB microSD cards also didn’t exist). Also, the serial number is very low — 0x960 is decimal 2,400. Other cards in the irregular batch also had similarly very low serial numbers, in the hundreds to thousands range. The chance of me “just happening” to get the very first microSD cards out of a factory is pretty remote. The serial number of the normal card, for example, is 0x9C62CAE6, or decimal 2,623,720,166 — a much more feasible serial number for a popular product like a microSD card. Very low serial numbers, like very low MAC ID addresses, are a hallmark of the “ghost shift”, i.e. the shift that happens very late at night when a rouge worker enters the factory and runs the production machine off the books. Significantly, ghost shifts are often run using marginal material that would normally be disposed of but were intercepted on the way to the grinder. As a result, the markings and characteristics of the material often look absolutely authentic, because the ghost material is a product of the same line as genuine material.

Furthermore, the manufacturer’s ID is 0x41 (ASCII ‘A’), which I don’t recognize (supposedly the SD group assigns all the MIDs but I don’t see a public list of them anywhere). The OEMID is also 0x3432, which is suspiciously ASCII ’42’ (one more than the hex value for the manufacturer ID). These hex/ascii confusions are possible signs that someone who didn’t appreciate the meaning of these fields was running a ghost shift making these cards.

Armed with this evidence, we confronted Kingston — both the distributor in China as well as the US sales rep. First, we wanted to know if these were real cards, and second, if they were real cards, why were the serialization codes irregular? After some time, the Kingston guys came back to us and swore these cards were authentic, not fakes, but at least they reversed their position on not offering an exchange on the cards — they took back the programmed cards and exchanged them for new ones, no further questions asked.

However, they never answered as to why their card ID numbers were irregular. While I know chumby is a small fry customer compared to the Nokias of the world, I think it’s still important that they answer basic questions about their quality control process even to the small fry. I had an issue once with an old version of a Quintic part being accidentally shipped to me, and once I could prove the issue to them, I received world-class customer service from Quintic, a full explanation, and an immediate and full exchange of the parts at their cost. That was exemplary service, and I commend and strongly recommend Quintic for it. Kingston, on the other hand, did not set an example to follow.

Normally, at this point, I would simply disqualify Kingston as a vendor, but I’m more persistent than that. It’s disconcerting that a high-profile, established brand would stand behind such irregular components. Who is to say SanDisk or Samsung wouldn’t do the same? Price erosion has been brutal on all the FLASH vendors, and as small fry I might be repeatedly taken advantage of as a sink for marginal material to improve the FLASH vendor’s bottom lines. Given the relatively high cost of these components, I needed to develop some simple guidelines for IQC (incoming quality control) inspection to accept or reject shipments from memory vendors, so I decided to do more digging to try and find ground truth.

The first thing I had to do was collect a lot of samples. The key is to attempt to collect both regular and irregular cards in the wild, so I went to the SEG / Hua Qian Bei district and wandered around the gray markets there. I bought about ten memory cards total from small vendors, at prices varying from 30-50 RMB ($4.40 – $7.30), most of them priced toward 30 RMB. The process of shopping for irregular cards itself was interesting. In talking to a couple dozen vendors, you learn a few things. First, Kingston as a brand is weak in China for microSD cards. Sandisk has done a lot more marketing in the microSD space, and as a result, it’s much easier to find Sandisk cards on the open market. The quality of the grey-market Sandisk cards are also typically more consistent. Second, the small vendors are entirely brazen about selling you well-crafted fakes. Typically, the bare cards are just sitting loose in trays in the display case; once you agree on the price and commit to buying the card, the vendor will toss the loose card into a “real” Kingston retail package, and then miraculously pull out a certificate, complete with hologram, serial numbers, and a kingston.com URL you can visit to validate your purchase, and slap it on the back of the retail package right in front of your eyes. Hey, it’s just like new! … I suppose the typical buyer in those markets is not an end user, but someone who is looking to make a quick buck reselling these cards at a hefty markup in a more reputable retail outlet.

One vendor in particular interested me; it was literally a mom, pop and one young child sitting in a small stall of the mobile phone market, and they were busily slapping dozens of non-Kingston marked cards into Kingston retail packaging. They had no desire to sell to me, but I was persistent; this card interested me in particular because it also had the broken “D” logo but no Kingston marking.

Above is a scan of the card and the package it came in (a larger image of the card can be seen below; it is “Sample #4”).

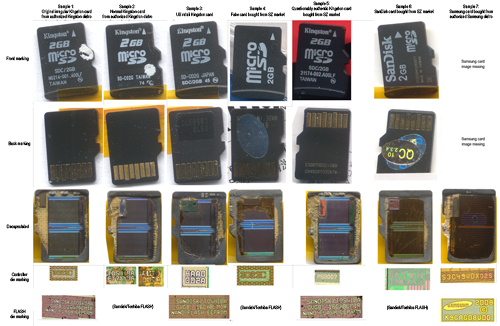

After collecting all the samples, I read out their card ID information, and then digested their packages with nitric acid. Below is the line-up of the cards I digested. Yes, my digestion technique is pretty crude. Actually, most of the damage to the card came from the cleaning process — I was using a Q-tip with acetone to remove the dissolved encapsulant and I had to get a little rough, which doesn’t do any favors for the bond wires. But…good enough for my purposes.

Click on the image above for a full-sized version.

Some notes on the cards above:

MID = 0x000041, OEMID = 0x3432, serial = 0x960, name = SD2GB.

MID = 0x000002, OEMID = 0x544D, serial = 0x9C62CAE6, name = SA02G

MID = 0x000002, OEMID = 0x544D, serial = 0xA6EDFA97, name = SD02G

MID = 0x000012, OEMID = 0x3456, serial = 0x253, name = MS

MID = 0x000027, OEMID = 0x5048, serial = 0x7CA01E9C, name = SD2GB

MID = 0x000003, OEMID = 0x5344, serial = 0x114E933D, name = SU02G

MID = 0x00001B, OEMID = 0x534D, serial = 0xB1FE8A54, name = 00000

That’s a lot of data for a blog post, but I figured more details are better for sharing, since I could find no central database for this kind of information on the web.

Here are the most interesting “high level” results from my survey:

Significantly, Kingston is revealed as simply a vendor that re-marks other people’s chips in its own packaging [clarification]. Every Kingston card surprisingly had a Sandisk/Toshiba memory chip inside, and the only variance or “value add” that could be found is in the selection of the controller chip. Oddly enough, of all the vendors, Kingston quoted with the best lead times and pricing — better than SanDisk or Samsung, despite the competition making all their own silicon and thereby having a lower inherent cost structure. This tells me that Kingston must be crushed when it comes to margin, which may explain why irregular cards are finding their way into their supply chain. Kingston is also probably more willing to talk to smaller accounts like me because as a channel brand they can’t compete against OEMs like Sandisk or Samsung for the biggest contracts from the likes of Nokia or RIMM. Effectively, Kingston is just a channel trader and is probably seen by SanDisk/Toshiba as a demand buffer for their production output. I also wouldn’t be surprised if SanDisk/Toshiba was selling Kingston “A-” grade parts, i.e., parts with slightly more defective sectors, but otherwise perfectly serviceable. As a result, Kingston plays a significant and important role in stabilizing microSD card prices and improving fab margins, but at some risk to their own brand image.

Overall, the MicroSD card market is a fascinating one, a discussion perhaps worth a blog post on its own. I’d like to point out to casual readers that the spot price of MicroSD cards is nearly identical to the spot price of the very same NAND FLASH chips used on the inside. In other words, the extra controller IC inside the microSD card is sold to you “for free”. The economics that drive this are fascinating, but in a nutshell, my suspicion is that incorporating the controller into the package and having it test, manage and mark bad blocks more than offsets the cost of testing each memory chip individually. A full bad block scan can take a long time on a large FLASH IC, and chip testers cost millions of dollars. Therefore, the amortized cost per chip for test alone can be comparable to the cost of silicon itself.

To ground this in solid numbers, suppose a production-grade memory tester costs one million dollars. If you take one million dollars and divide it by the number of seconds over a five year period (a typical depreciation lifespan for such equipment), the equipment “costs” $0.00634 per second. Thus, a thirty second test costs you $0.00634/second x 30 seconds = $0.19. This is comparable to the raw die cost of the controller IC, according to my models; and by making the controllers very smart (the Samsung controller is a 32-bit ARM7TDMI with 128k of code), you get to omit this expensive test step while delivering extra value to customers — I love the fact that when I put on my linux kernel hacker hat, I can be completely oblivious to the existence of bad blocks and use mature filesystems like ext3 instead of JFFS2, at no extra cost to end customers like you. Isn’t it fun to connect the dots, all the way from silicon die markings to the linux kernel to end users, and all the businesses in between?

In the end, I’d have to say that both SanDisk and Samsung look like they might be superior wholesale vendors to Kingston

for memory cards due to their more direct control of their respective supply chains. Unfortunately, you can’t buy Samsung-branded microSD

cards on the retail market, as far as I know — Samsung only sells their cards to wholesalers who then rebrand and/or resell the card, and like Kingston these non-OEM brands may blend their vendors so it’s hard to say if you’re getting the best card or simply a usable card.

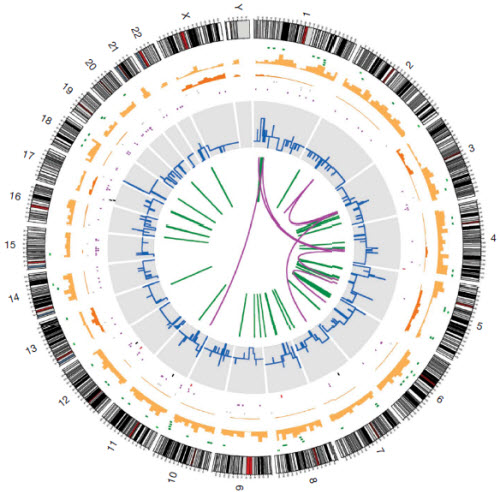

One Mutation per 15 Cigarettes Smoked

Friday, January 22nd, 2010Now that’s a memorable factoid. Nature recently published a paper titled “A small-cell lung cancer genome with complex signatures of tobacco exposure” (Nature 463, 184-190 (14 January 2010), Pleasance et al), which as its title implies, contains the summary of the sequence of a cancer genome derived from a lung cancer tumor. It’s an interesting read; I can’t claim to understand it all. At a high level, they found 22,910 somatic substitutions, 65 insertions and deletions, 58 genomic rearrangements, and 334 copy number segment variations were identified; as I understand it, these are uncorrectable errors, i.e. the ones that got past the cell’s natural error-correction mechanisms. That’s out of about 3 gigabases in the entire genome, or an accumulated error rate of about 1 in 5 million.

I’m not an expert on cancer, but the way it was explained to me is that basically every cell has the capacity to become a cancer, but there are several dozen regulatory pathways that keep a cell in check. In a layman sort of way, every cell having the capacity to become a cancer makes sense because we come from an embryonic stem cell, and tumorigenic cancer cells are differentiated cells that have lost their programming due to mutations, thereby returning to being a (rogue) stem cell. So, a cancer happens when a cell accumulates enough non-fatal mutations such that all the regulation mechanisms are defeated. Of course, this is basically a game of Russian roulette; some cells simply gather fatal mutations and undergo apoptosis. In order to become a cancer cell, it has to survive a lot of random mutations, but then again there are plenty of cells in a lung to participate in the process.

Above: a map of the mutations found in the cancer cell. The 23 chromosomes are laid end to end around the edge of the circle. There’s a ton of data in the graph; for example, the light orange bars represent the heterozygous substitution density per 10 megabases. A higher resolution diagram along with a more detailed explanation can be found in the paper.

The tag line for this post is lifted from the discussion section of the paper, where they assume that lung cancer develops after about 50 pack-years of smoking, which roughly translates to the ultimate cancer cell acquiring on average one mutation every 15 cigarettes smoked. Even though this is an over-simplification of the situation, the tag line is memorable because it makes the impact of smoking seem much more immediate and concrete: it’s one thing to say on average, in fifty years, you will get cancer from smoking a pack a day; it’s another to say on average, when you finish that pack of cigarettes, you are one mutation closer to getting cancer.

The Enlightening Bridge Between Art And Work

Tuesday, January 12th, 2010As I was driving home today, I enjoyed a delightful morsel on NPR’s All Things Considered about the The Enlightening Bridge Between Art and Work by Alain De Botton (it’s better listened to than read, imo).

Here’s an excerpt of the spot that I found particularly poignant:

Two centuries ago, our forebears would have known the precise history and source of almost every one of the limited number of things they ate and owned. They would have been familiar with the pig, the carpenter, the weaver, the loom and the dairymaid. The range of items available for purchase may have grown exponentially since then, but our understanding of their genesis has grown ever more obscure. We are now as imaginatively disconnected from the production and distribution of our goods as we are practically in reach of them, a process of alienation which has stripped us of opportunities for wonder, gratitude and guilt.

That last sentence, I think, resonates strongly with my personal motivation as a Maker. I dive deeply into the supply chain, learning the processes and understanding the people behind our Things, because it enables me to once again feel the wonder, gratitude, and guilt for the Things we otherwise take for granted. Wonder at the skill of craftsmen and the cleverness of designers; gratitude for the passion and hard work of my peers; and guilt for the sacrifice, waste, and unsustainable practices motivated by an obscure system of perverse economic incentives.

Mythbusting Personalized Genomics

Sunday, October 11th, 2009It’s the year 2009, and I’m wondering: where is my flying car? After all, Hollywood reels from the 60’s and 70’s all predicted that flying cars are what I’d be using to get around town these days. Of course, automotive technology isn’t the only victim of Hollywood hype. The potential impact of personalized genomics has been greatly overstated in movies like GATTACA. This has lead to the pervasive myth that your genome is like a crystal ball, and somehow your fate is predestined by your genetic programming. Recently, my perlfriend co-authored a paper in Nature (“A Personalized Medicine Research Agenda”, Nature Vol 461, October 8 2009), comparing Navigenics’ and 23andMe’s “Direct to Consumer” (DTC) personal genomics offerings. She’s qualified to offer deep insight into personal genomics, since she designed the original Illumina bead chip used by leading companies to generate their DTC genetic data, and she is also the person who made sense of the first complete diploid human genome sequence (1 2). She’s sort of the biology equivalent of the reverse engineer who takes binary sequences and annotates meaning into the disassembled binary sequences. So, let the mythbusting begin.

Myth: having your genome read is like hex-dumping the ROM of your computer. Many people (I was one of them) have the impression that “reading your genome” means that at the end of the day someone has a record of all the base pairs of DNA in my genome. This is called a “full sequence”. In reality, full sequencing is still cost-prohibitive, and instead a technique called “genotyping” is used. Here, a selective diff is done between your genome and a “reference” human genome, or in other words, your genome is simply sampled in potentially interesting spots for single-point mutations called Single Nucleotide Polymorphisms (SNPs, pronounced “snips”). In the end, about 1 in 3000 base pairs are actually sampled in this process. Thus, the result of a personalized genomic screen is not your entire sequence, but a subset of potentially interesting mutations compared against a reference genome. This naturally leads to two questions: first, how do you choose the “interesting subset” of SNPs to sample? And second, how do we know the reference genome is an accurate comparison point? This sets us up to bust another two myths.

Myth: We know which mutations predict disease. Herein lies a subtle point. Many of the mutations are simply correlative with disease, but not proven to be predictive or causal with disease. The truth is that we really don’t understand why many genetic diseases happen. For poorly understood diseases (which is still most of them), all we can say is that people who have a particular disease tend to have a certain pattern of SNP mutations. It’s important not to confuse causality with correlation. Doing so might lead you to conclude, for example, that diet coke makes you fat, because diet coke is often consumed by people who are overweight.

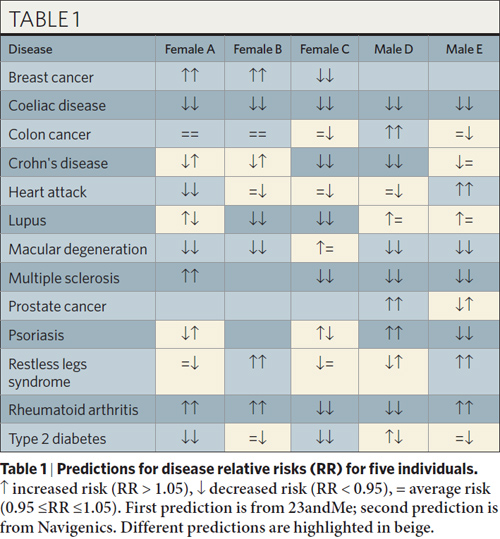

Thus, there are two echelons of understanding that can come from a genotype: disease correlations, and disease causes. The majority of SNP mutation-based “predictions” are correlative, not causative. As a result, a genotype should not be considered a “crystal ball” for predicting your disease future; rather, it is closer to a “Rorschach blot” that we have to squint and stare at for a while before we can make a statement about what it means. The table below from the paper illustrates how varied disease predictions can be as a result of these disagreements on the interpretation of mutation meanings.

Myth: the “reference genome” is accurate reference. The term “reference genome” alone should tip you off on a problem: it implies there is such a thing as “reference people”. Ultimately, just a handful of individuals were sequenced to create today’s reference genome, and most of them are of European ancestry. As time goes on and more full sequence genetic data is collected, the reference genome wlll be merged and massaged to present a more accurate picture of the overall human race, but for now it’s important to remember that a genotype study is a diff against a source repository of questionable universal validity, partially because it’s questionable if there is such a thing as a “reference human”, i.e. there are structural variations and some SNPs have different frequencies in different populations (e.g. the base “A” could dominate in a European population, but at that same position, the base “G” could dominate in an African population). It’s also important to keep in mind that the “reference genome” has an aggregate error rate of about 1 error every 10,000 base pairs, although to be fair the process of discovering a disease variant usually cleans up any errors in the reference genome for the relevant sequence regions.

So now you can see that in fact “reading your genome” is less of looking into a crystal ball and more of staring at a Rorschach blot obscured by cheesecloth (i.e., the genome is simply sampled and not sequenced). And, even if we could remove the cheesecloth and sequence the genome such that we knew every base pair, it would still be … a Rorschach blot, but in high resolution. It will be decades until we have a full understanding of what all the sequences mean, and even then it’s unclear if they are truly predictive.

Here lies perhaps the most important message, and a point I cannot make fine enough: in most situations, environment has as much, perhaps even more, to do with whom you are, what you become, and what diseases you may develop than your genes. If there is any upside to personal genomics, it won’t be due to crystal ball predictions. It will be the lifestyle changes it can encourage. If there’s one thing I’ve learned from dating a preeminent bioinformaticist, it’s that no matter your genetic makeup, most common diseases can be prevented with proper diet and exercise.