I recently saw a demo of Android booting up in a CoWare environment, and I couldn’t help but notice this line in the Android boot console:

... Freeing init memory: 96K init: HOW ARE YOU GENTLEMEN init: reading config file ...

That’s a little scary. If you don’t get the reference, it’s the infamous first words of CATS, followed by the immortal phrase “all your base are belong to us“.

I mean, I love the google search application, but I am a little bit disturbed by the masses of people trusting all their bits to google — their email, their desktops, their photos … soon their phones (no, I don’t use gmail — I must be the last person on earth who doesn’t — but the idea of ads showing up based on what’s in my email is disquieting for a variety of reasons). And I think that surely the Android developers cannot claim ignorance to the context of the phrase: all your base are belong to us // you are on your way to destruction // you have no chance to survive make your time.

Now, Don’t be Evil!

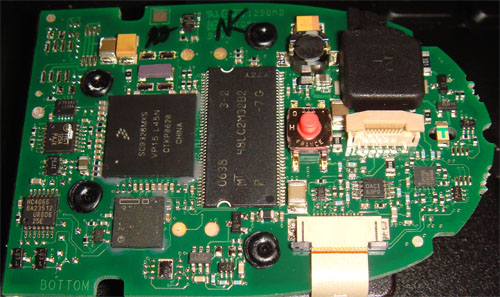

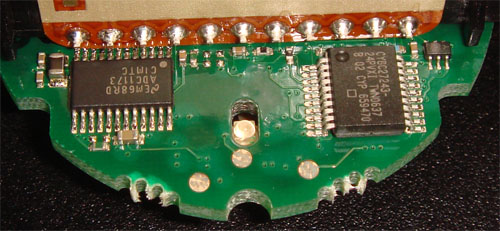

Incidentally, CoWare is a really neat tool; one of their other demos is a hardware simulation of the chumby platform. It’s absolutely amazing that they have a cycle-accurate simulation of the chumby hardware platform that boots our code and runs almost real-time. Since it’s a hardware simulation, you can jump in and inspect the state of signals between components, wiggle lines, and set breakpoints based on hardware state (as well as software state). This is one of those cool things that come out of having an open platform; without access to our source code and documentation, creating this demo without the help of chumby would have been much more difficult. And while some consumer electronics companies would go batty over someone emulating their platform, I say to them hats off for such a clever hack and such a powerful product.